- Home

- Software Modules

- HR & Payroll Module

- ERP Services

- Customers Support

- New Customer? The Starting Point

- Help – All Modules

- Help – HRMS & Payroll

- Important Information – Help

- Manage Employees – Help

- Leave Calculations – Help

- Absence Calculations – Help

- Loan Process – Help

- Addition \ Deduction – Help

- Air Ticket – Help

- EOS Calculations – Help

- Other Activities in HRMS – Help

- TimeSheet – Help

- Payroll – Help

- Setup – Help

- Post HRMS to Accounting – Help

- Manual of HRMS – Help

- Protect Your Data

- Remote Support

- QuickBooks integration Rules

- Certified Trainer \ Resellers

- Very Important Instructions

- Terms and Conditions

- Hinawi ERP Exams

- Accounting Module Exams

- Fixed Assets Module Exams

- Real Estate Module Exams

- School Module Exams

- Garage Module Exams

- HRMS Exams

- Leave Activity Exam

- Stop Release Activity Exam

- Loan Activity Exam

- Absence Activity Exam

- Absconded Activity Exam

- Addition Deduction Activity

- Air Ticket Activity Exam

- TimeSheet Activity Exam

- End of Service Activity Exam

- Comprehensive HRMS Exam

- Screenshot HRMS Exam

- Leave & Absence Calculation affecting in Payroll

- Leave & Absence Calculation – عربي

- Hinawi ERP Standard Exam

- Universities

- Special Offer

العربية

العربية

The Manufacturing module Help Page

Setup

Feature setup is essential for setting the company’s regulations, arrangements, and control policy.

Before recording any operations, the user must set up the company file.

If these settings are not made, the customer may find that the results do not comply with its policies and need to re-enter its operations.

Therefore, settings are vital when using the software. It’s very important to understand this. The setup unit is the most important step and must be done before using the software.

Streamline Your Manufacturing Process With Hinawi ERP

Stage one:

Settings

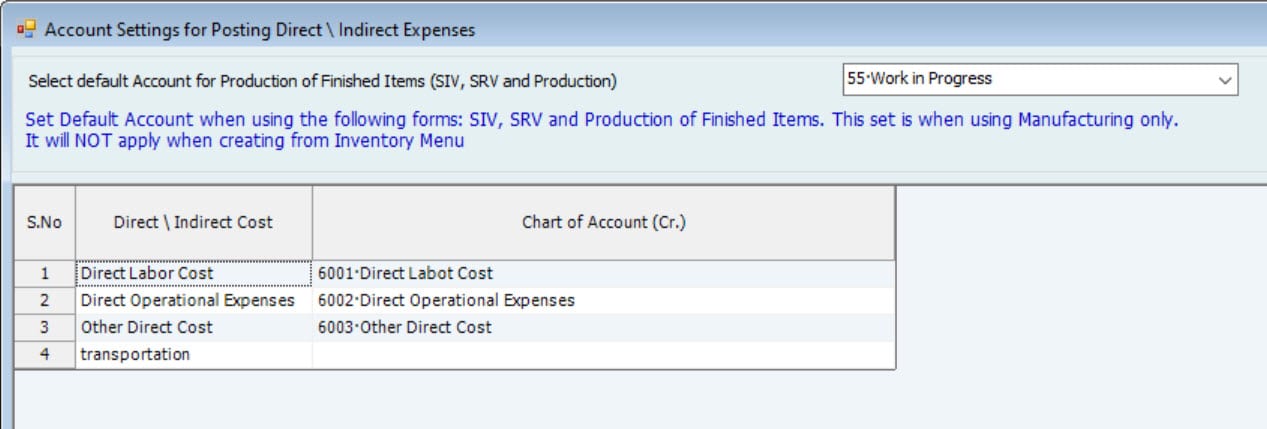

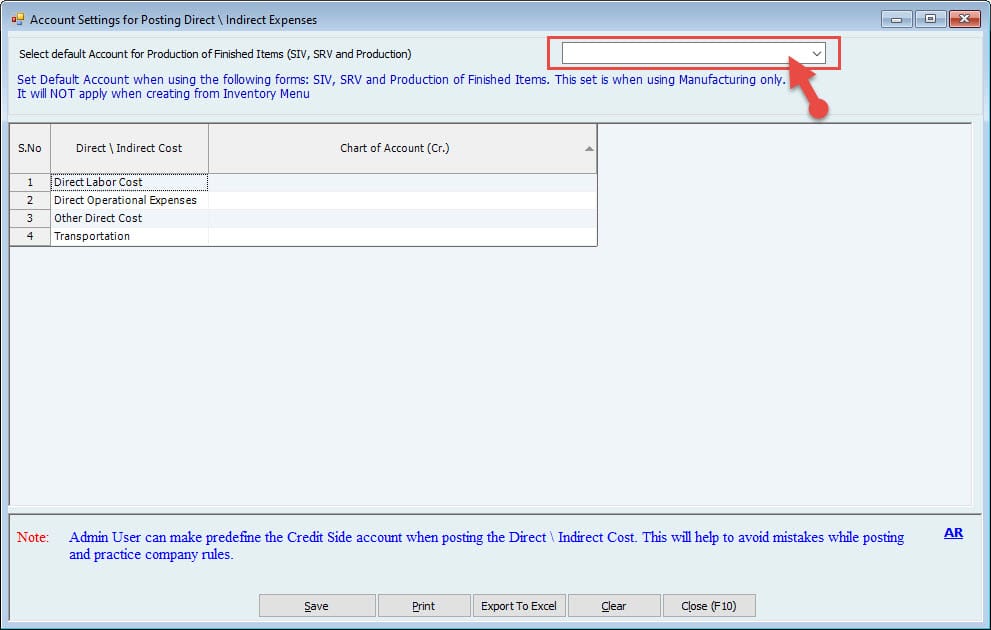

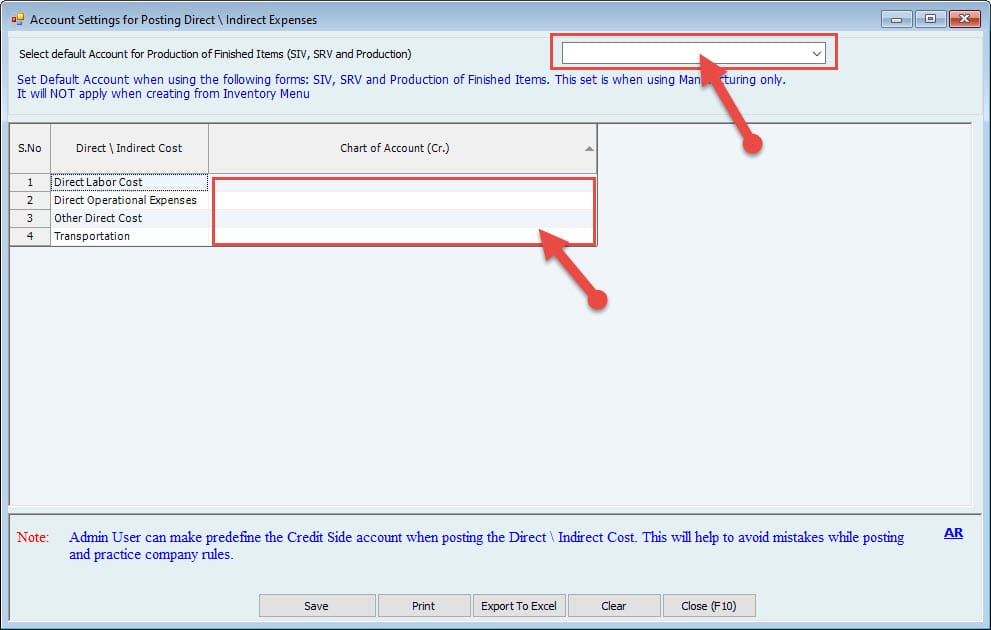

- Setup of Accounts:

Users must make a Setup from File Menu -> Setup Modules -> Manufacturing Settings. The System will automatically read the Default Account in SIV \ SRV \ Production from this Setup. The User cannot change the default Account from the SIV \ SRV \ Production form. There are no accounting entries in this step.

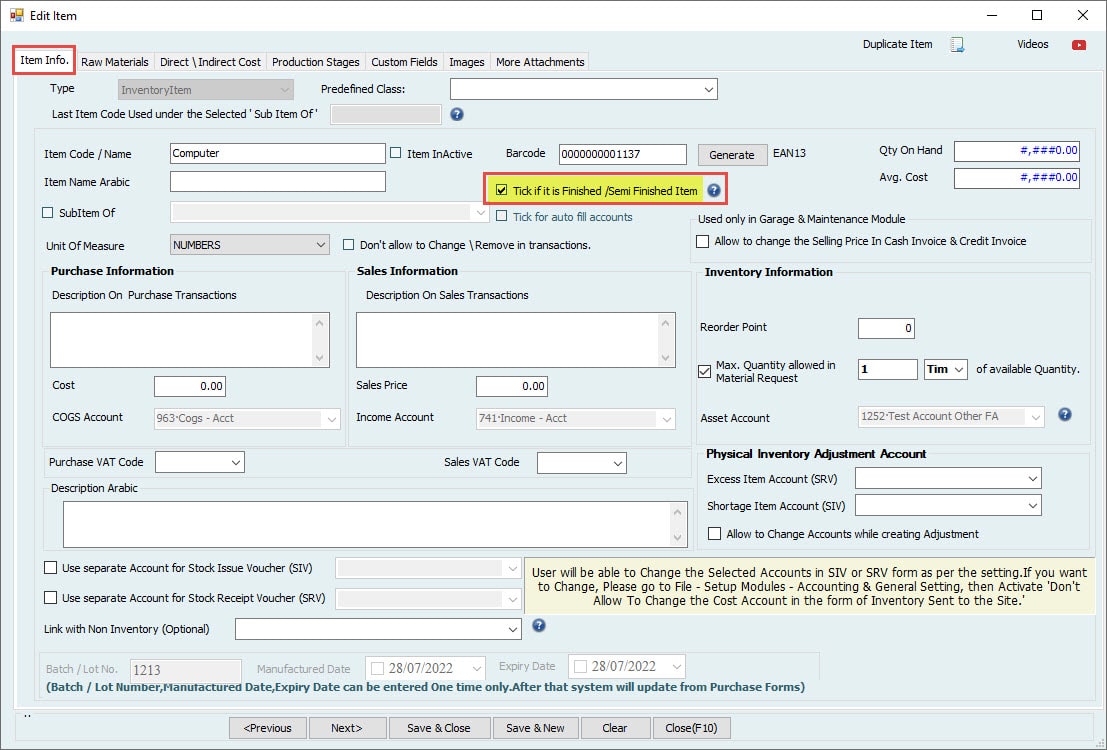

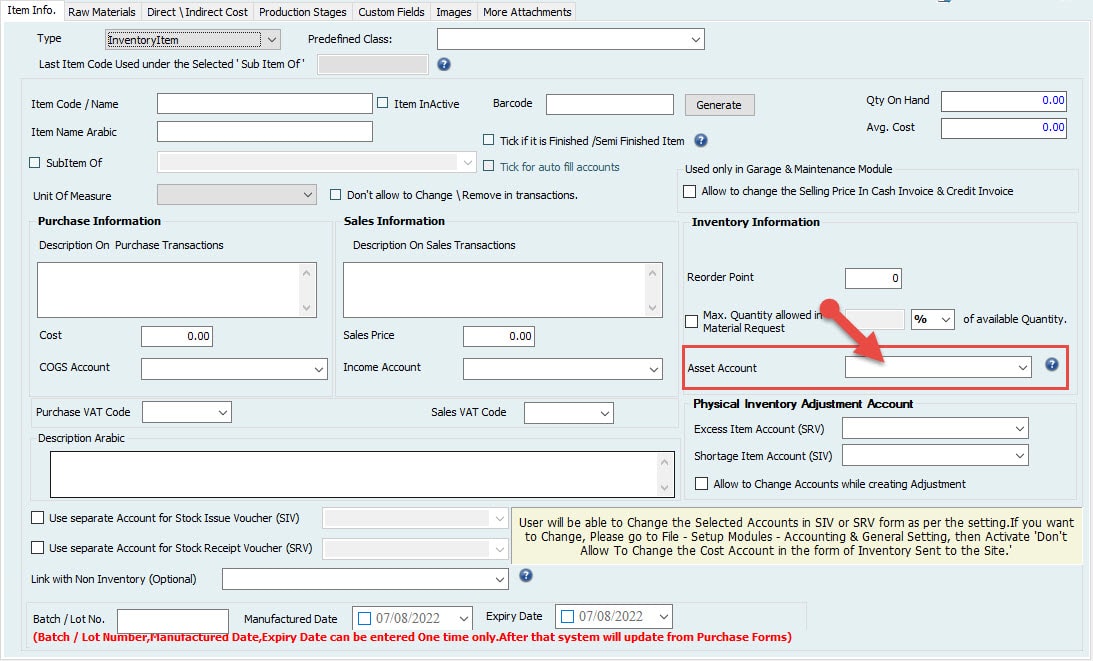

- Create the Finished \ Semi Finished Item.

While creating the Item, the User must select the option (Tick if it is a Finished \Semi Finished Item). There are no accounting entries in this step.

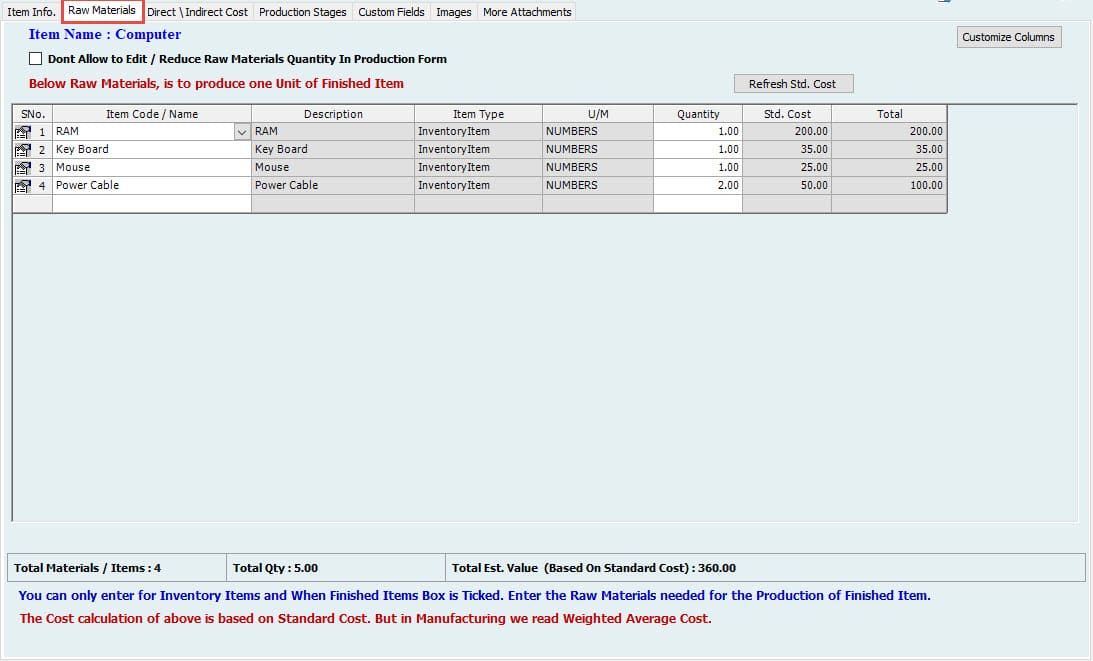

- Enter the Raw Materials:-

In the Raw Materials Tab, enter the necessary Item and Quantity to Produce One (1) Unit. In the Raw materials, Cost is calculated based on the Standard Cost. In the Production, we read the Average Cost of the Raw Materials. There are no accounting entries in this step.

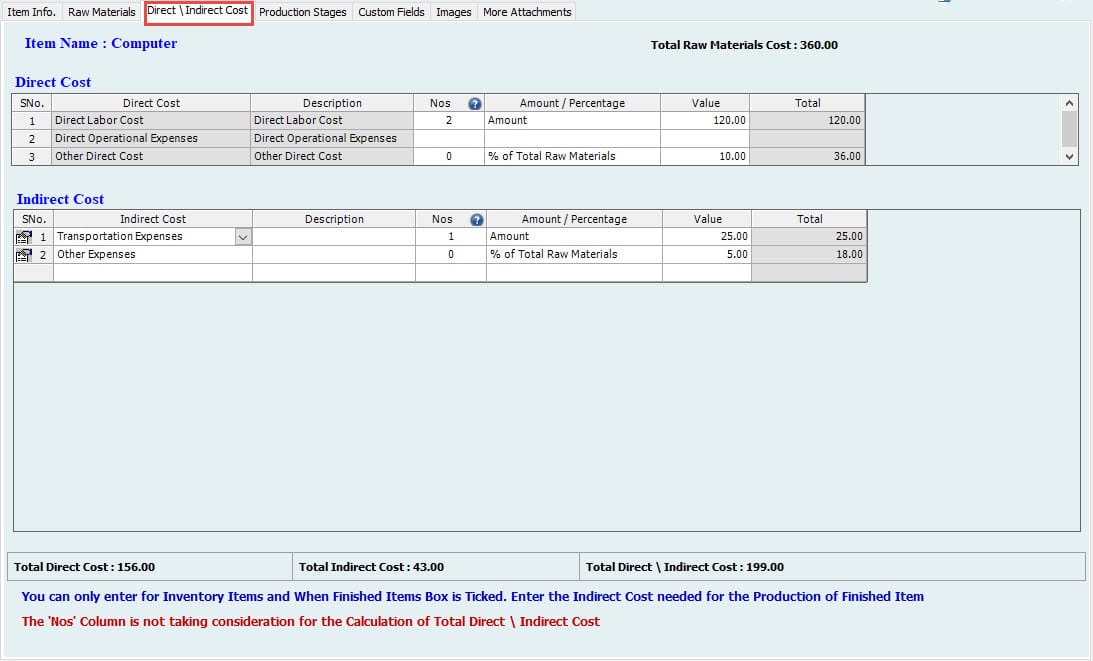

- Enter Direct \ Indirect Cost:

Form the Direct \ Indirect Cost Tab. Direct Cost Includes the Following:

- Direct Labor Cost

- Direct Operational Expenses

- Users can create Other Direct Cost Indirect Costs by Pressing F2 or from General List. The User can enter by Amount or Percentage of Raw Materials. There are no accounting entries in this step.

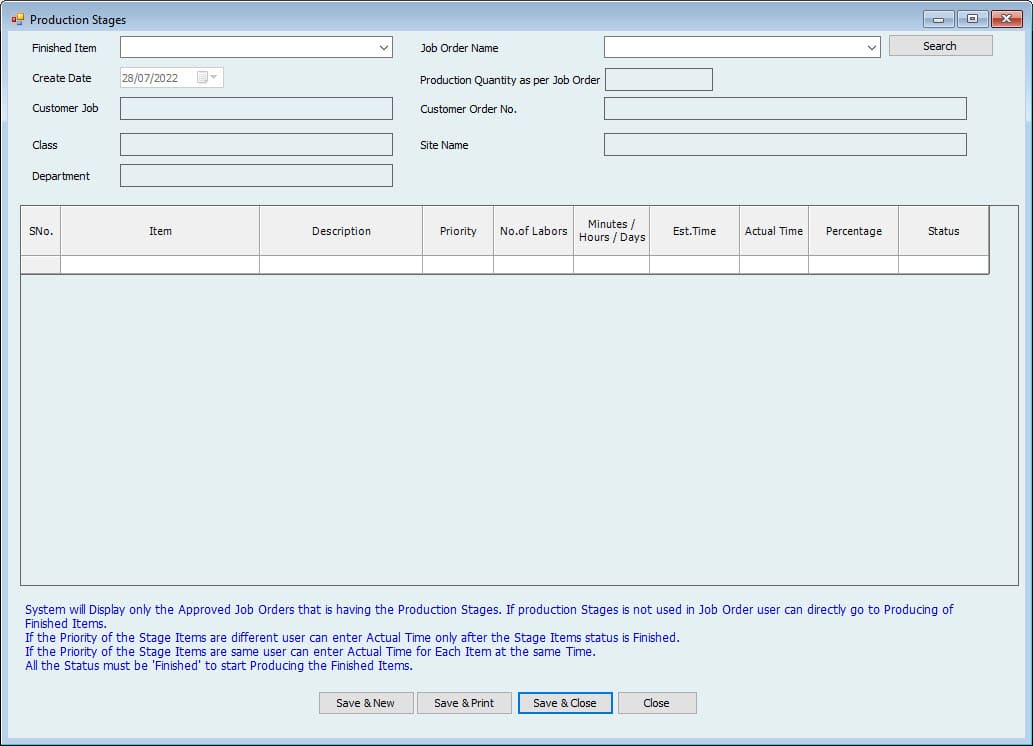

- Enter the Production Stages:

Production stages are not mandatory. Users can use this function if this Item has to be finished by the Production stages. The User can define the Priority of each production stage of this Item.

Stage Two:

Activities

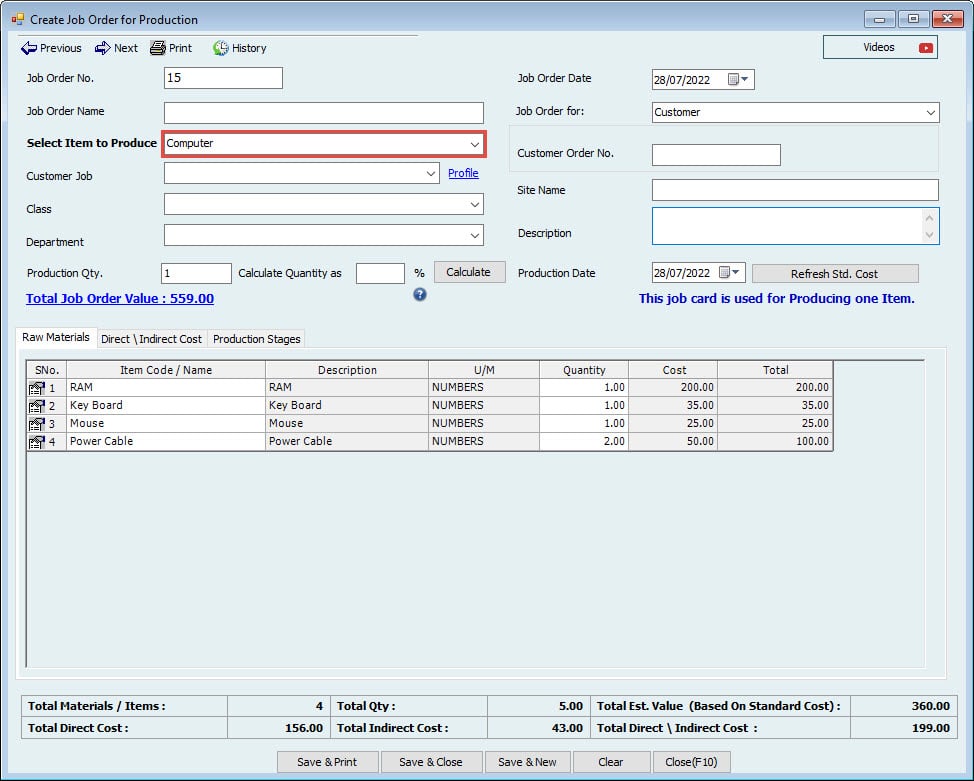

- Create Job orders for Production.

In the Job order, the User must select the Item for Production. The System will automatically read the Raw materials and Direct \ Indirect Costs from the Item Profile chosen for 1 Quantity. The User can enter the No of Quantity to be produced for this Job Order. The System will automatically calculate the Raw materials and Direct \ Indirect Costs based on the Production Quantity.

Option to Edit, Approve, Print, and Void Job Orders. Users can edit the Job Order if it's not linked with the Stock Issue Voucher. Users can change the Quantity and Delete one or more items.

After that, the User must enter the production stages if the Item is predefined with production stages. The System will allow the Produce Items only after finishing all the Production Stages. The System will display only the Approved Job Orders. There are no accounting entries in this step.

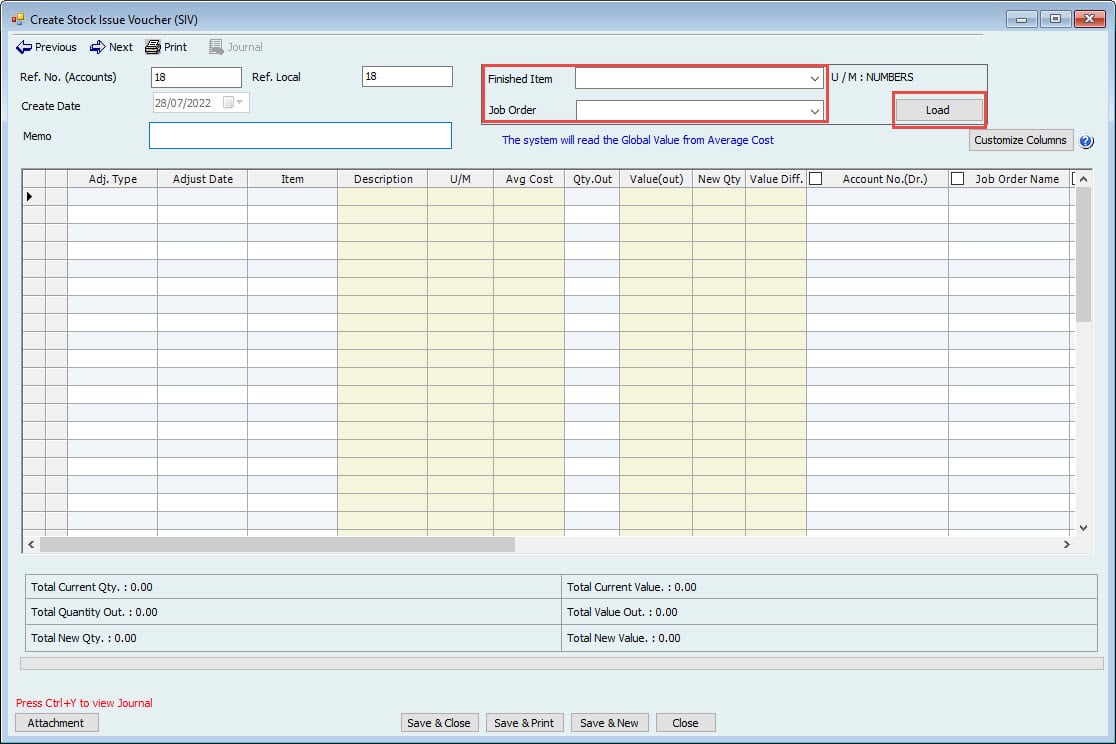

- Issue Items:

Issue Items for the Production (Using Stock Issue Voucher Form). The User must select the Item for Production.

The System will display the Approved Job Orders, and the User can create multiple Stock Issue Vouchers for one Job Order. However, it cannot exceed the maximum Quantity of the Job order.

Accounting entries in this step

Dr. WIP A/C 57000 Default Account (Reading from Setup).

Cr. Inventory RM Account (Reading from Predefine Account from Item Profile).

The User can void the Stock Issue Voucher. If Production is made, we must first void the Production; then only we can void the SIV.

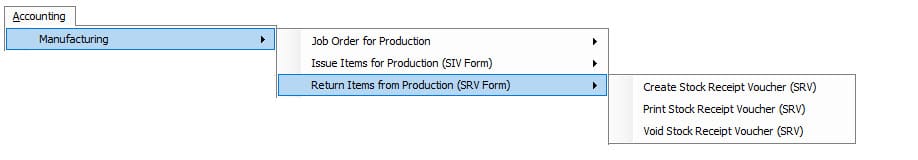

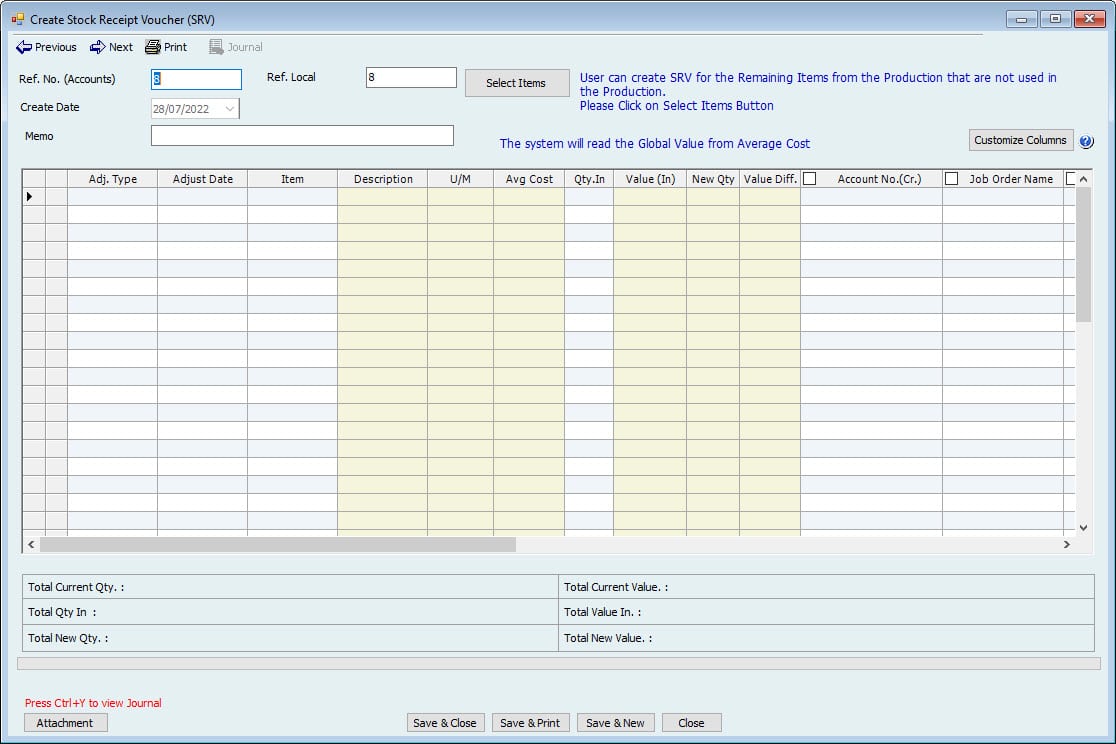

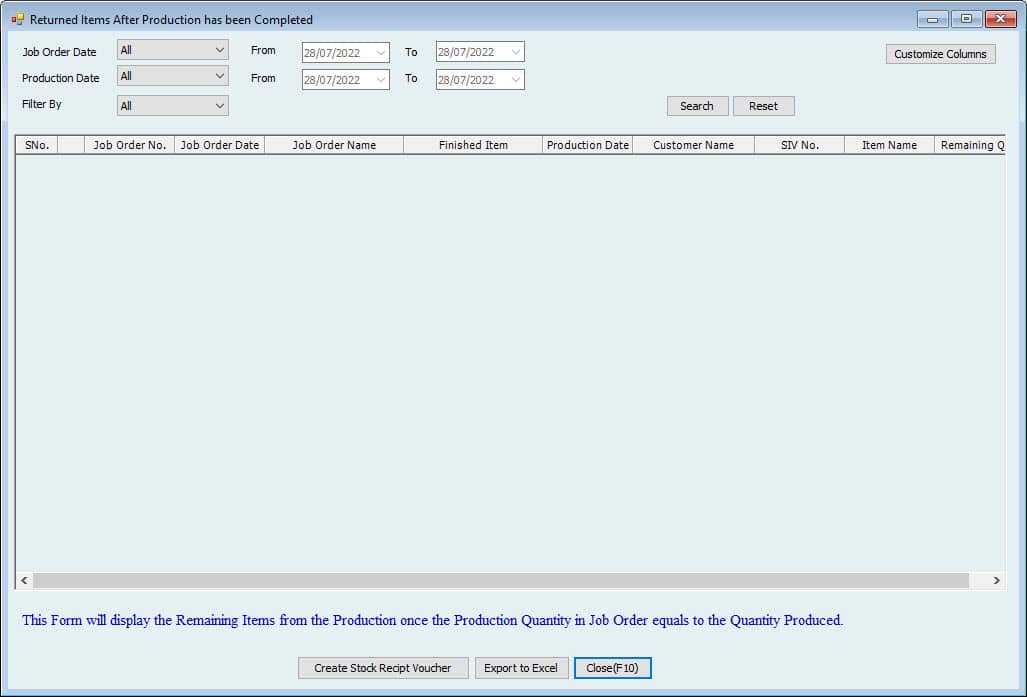

Return extra Items from Production:

Return the Items from Production using Stock Receipt Voucher (SRV) Form. This form can be used at any time of Production until we reach the Production Quantity. The User must select the Items from the Stock Issue Voucher related to this Job Order. The User can only create Stock Receipt Voucher for each SIV. Multiple SIVs are not allowed.

The User can void the Stock Receipt Voucher.

If the Stock Receipt Voucher is created from the List of Remaining Items, the User cannot void the SRV.

Accounting entries in this step:

Dr. Inventory RM Account (Reading from Predefine Account from Item Profile)

Cr. WIP A/C 57000 Default Account (Reading from Setup)

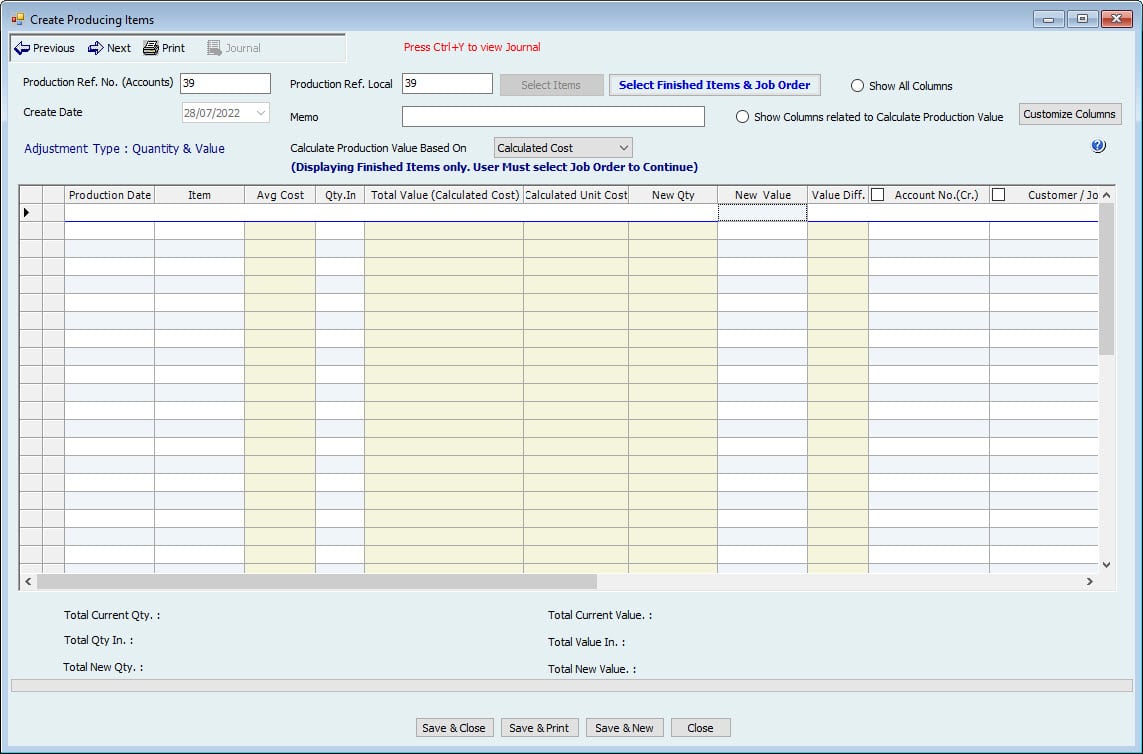

Production Finished Items:

The User can produce multiple Production until the Job Order Quantity is reached. Users cannot add more Quantity than the SIV Quantity.

Users can enter Less Quantity than the SIV Quantity. If the Production Quantity Equals Job Order Quantity and some Item Quantity is left, the User can create Stock Receipt Voucher for the Remaining Items after Production. The User can void the Production, but if the Stock Receipt Voucher for the remaining items is completed, the User cannot Void Production.

Accounting entries in this step

Dr. Inventory Finished Items Account (Reading from Predefine Account from Finished Item Profile)

Cr. WIP A/C 57000 Default Account (Reading from Setup)

Create Stock Receipt Voucher (SRV) for the Remaining Items after Production.

Accounting entries in this step:

Dr. Inventory RM Account (Reading from Predefine Account from Item Profile)

Cr. WIP A/C57000 Default Account (Reading from Setup)

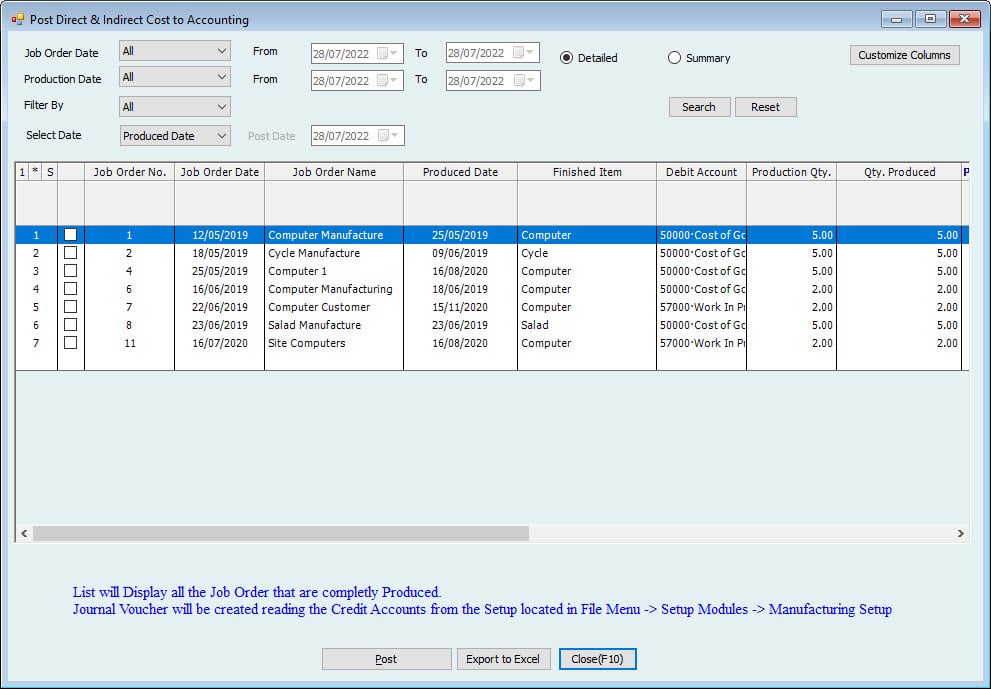

Post the Direct \ Indirect Cost to Accounting:

After the Production for the Job Order is complete, the User has to Post the Direct \ Indirect Cost to Accounting as Journal Voucher.

Accounting entries in this step:

Dr. WIP A/C 57000 Default Account (Reading from Setup)

Cr. Cost or Operational Account for Direct \ Indirect Cost (Read from Setup)

WIP A/C 57000 | |||||

Description | Form Name | Trans. # | Dr. | Cr. | Balance |

Issue Raw Materials Items for production. Cr. Inventory RM | SIV | 1 | 1000 | 1000 | |

Return Raw Materials Items from Productions. Dr. Inventory RM | SRV | 2 | 100 | 900 | |

Produced Finished Items Amount 4000 (As 900 from RM and 3100 from Direct & Indirect Expenses) Dr. Inventory Finished Items | Production Form | 3 | 4000 | – 3100 | |

Close Direct \ Indirect Material Cr. Cost \ Operation Expenses (User will decide) | JV | 4 | 3100 | 00 |

Inventory Raw Materials | |||||

Description | Form Name | Trans. # | Dr. | Cr. | Balance |

Opening Balance |

| 1000 | |||

Issue Raw Materials Items for productions | SIV | 1 | 1000 | 00 | |

Return Raw Materials Items from Productions | SRV | 2 | 100 | 100 |

Inventory Finished Items | |||||

Description | Form Name | Trans. # | Dr. | Cr. | Balance |

Producing Finished Items | Production Form | 3 | 4000 | 4000 |

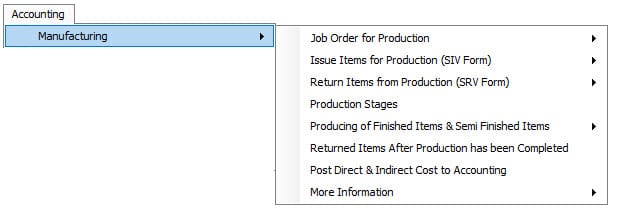

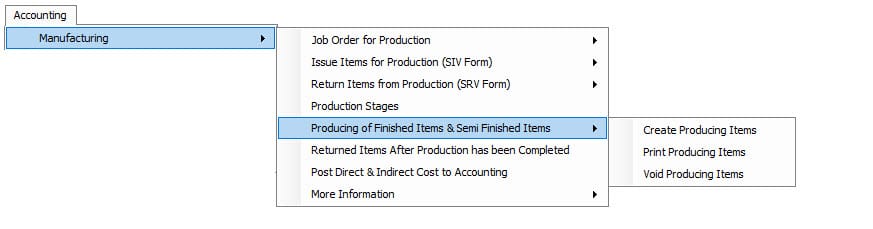

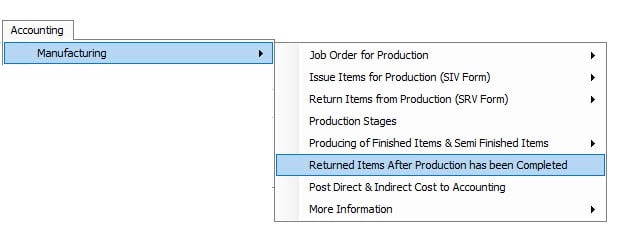

Manufacturing

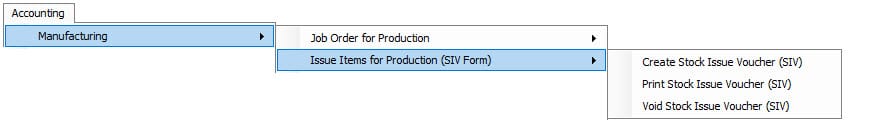

To make manufacturing,

Go To Accounting-->Manufacturing

Features:

- Job Order for Production

- Issue Items for Production (SIV Form)

- Return Items from Production (SRV Form)

- Production Stages

- Producing of Finished Items & Semi-Finished Items

- Returned Items After Production has been completed

- Post Direct & Indirect Cost to Accounting

Manufacturing Module Starts with the Item Creation.

While creating the Item, we must select the option (Tick if it is a Finished /Semi Finished Item).

After that, we must enter the Raw Materials needed for this Item from the Raw Materials Tab, Enter the Item and Quantity needed to Produce 1 Unit. In the Raw materials, Cost is calculated based on the Standard Cost.

In Production, we are reading the Average Cost of the Raw Materials.

After that, enter the Direct \ Indirect Cost form in the Direct \ Indirect Cost Tab.

Direct Cost Includes the Following:

1. Direct Labor Cost

2. Direct Operational Expenses

3. Other Direct Cost

The User can create indirect Cost by Pressing F2 or

from General List.

The User can enter by Amount or Percentage of Raw Materials.

After that, we must enter the Production Stages. Production stages are not mandatory. It can be used if this Item must be finished stage by stage.

The User can define the Priority of each stage in the Production of this Item.

After that, Create a Job order for Production.

Create Job Order for Production

To Create a Job Order;

Go to Accounting--> Manufacturing-->Job Order for Production-->Create Job Order for Production.

In the Job order, the User must select the Item for Production. The System will automatically read the Raw materials and Direct \ Indirect Costs from the Item Profile of the selected Item for 1 Quantity.

The User can enter the No of Quantity to be produced for this Job Order. The System will automatically calculate the Raw materials and Direct \ Indirect Costs based on the Production Quantity.

Option to Edit, Approve, Print, and Void Job Orders.

The job Order can be edited until Stock Issue Voucher for this Job order is created. Users can change the Quantity and Delete one or more items.

After that, if production Stages are defined for this Item, the User must enter the Production Stages.

The System will allow to Produce Items only after all the Production Stages are finished.

The System will display only the Approved Job Orders.

Issue Items:

Issue Items for the Production (Using Stock Issue Voucher Form).

The User must select the Item for Production.

The System will display the Approved Job Orders, and the User can create multiple Stock Issue Vouchers for one Job Order. However, it cannot exceed the maximum Quantity of the Job order.

Accounting entries in this step

Dr. Reading from Setup

Cr. Inventory RM Account (Reading from Predefine Account from Item Profile)

The User can void the Stock Issue Voucher.

If Production is made, we must first void the Production. Then only we can void the SIV.

Return extra Items from Production:

Return the Items from Production using Stock Receipt Voucher (SRV) Form.

This form can be used at any time of Production until we reach the Production Quantity.

The User must select the Items from the Stock Issue Voucher related to this Job Order.

The User can only create Stock Receipt Voucher for each SIV.

Multiple SIVs are not allowed.

The User can void the Stock Receipt Voucher.

If the Stock Receipt Voucher is created from the List of Remaining Items, the User cannot void the SRV.

Accounting entries in this step

Dr. Inventory RM Account (Reading from Predefine Account from Item Profile)

Cr. Reading from Setup

Production Finished Items:

The User can produce multiple Production until the Job Order Quantity is reached.

Users cannot add more Quantity than the SIV Quantity.

Users can enter Less Quantity than the SIV Quantity.

If the Production Quantity Equals Job Order Quantity and some Item Quantity is left, then the User can create Stock Receipt Voucher for the Remaining Items after Production.

The User can void the Production, but if the Stock Receipt Voucher for the remaining items are created, the User cannot Void Production.

Accounting entries in this step

Dr. Inventory Finished Items Account (Reading from Predefine Account from Finished Item Profile)

Cr. (Reading from Setup)

Create Stock Receipt Voucher (SRV) for the Remaining Items after Production.

Accounting entries in this step:

Dr. Inventory RM Account (Reading from Predefine Account from Item Profile)

Cr. Default Account (Reading from Setup)

Post the Direct \ Indirect Cost to Accounting:

After the Production for the Job Order is complete, the User has to Post the Direct \ Indirect Cost to Accounting as Journal Voucher.

Accounting entries in this step:

Dr. (Reading from Setup)

Manufacturing Road Map | ||||||||

| Activities | Posting Method to Accounting. (Automatic or Manual) | Need Approval Step? | Option to change to Unapprove? | Post to Accounting Menu. (Post Approved Activities). | Can Edit after approval? | Can Void after approval? | Can Edit after Posted to Accounting? | Can Void after Posted to Accounting? |

| Job Card | No Accounting Effect. | Yes | Yes | Not Applicable | No, User can make Unapprove to change status to Created. | Yes, if status is created. | Not Applicable | Not Applicable |

| Issue Items for Productions (SIV) | Automatic Only | No Its Auto Approved | No | Posted Automatically | No | Yes | No | No |

| Return Items from Productions (SRV) | Automatic Only | No Its Auto Approved | No | Posted Automatically | No | Yes | No | No |

| Production Stages | No Accounting Affect. | No | No | Not Applicable | No | No | Not Applicable | Not Applicable |

| Producing of Finished Items | Automatic Only | No Its Auto Approved | No | Posted Automatically | No | Yes | No | No |

| Return Items after Productions | Automatic Only | No Its Auto Approved | No | Posted Automatically | No | No | No | No |

| Post Direct and Indirect Cost | Automatic Only | No Its Auto Approved | No | Posted Automatically | No | No | No | No |

| Accounting (Create JV) | Automatic | No Its Auto Approved | No | Posted Automatically | Yes | Yes | Yes | Yes |

| Manual | Approval Option is not required | No | Yes | The approval step is not required | Yes | Yes | Yes | |

Automatic Created JV. | Automatic only | No Its Auto Approved | No | Posted Automatically | No | No | No | No |

The delete option is not available either before or after any action. |